In the fast-paced environment of fast food restaurants, maintaining the right temperature in freezers and coolers is critical. Any deviation from the optimal temperature range can lead to food spoilage, financial losses, and health risks. However, recurring issues with refrigeration equipment—such as frequent door openings, equipment shutdowns, or mechanical failures—pose significant challenges.

Understanding the Challenges: Introduction to Refrigeration Anomaly Detection

To proactively detect and address these issues, ACTuate Facility Technologies, a company specializing in facility energy and system performance optimization for small to midsize buildings optimization, approached us for our data analytics expertise. Through our collaboration, we’re leveraging their extensive dataset from various fast food restaurants to develop sophisticated methods for detecting unusual behavior in refrigeration equipment, such as walk-in and reach-in freezers and coolers.

One of the major challenges in monitoring these systems is the variability in temperature that can occur during normal operations. For example, opening a freezer’s door for a few moments can cause a brief spike in temperature, which typically doesn’t indicate a problem. Regular defrost cycles can have a similar impact to the normal variability of the temperature data. However, more sustained deviations or unusual patterns might signal an issue that requires attention.

To address this, we need a system that can differentiate between normal fluctuations and potential problems—without the need for significant hardware additions. This is where data modeling and mathematical optimization come into play, allowing us to work effectively with the existing sensors and equipment.

Showcasing Temperature Monitoring Through Data Modeling

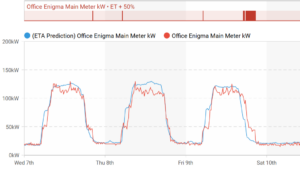

Based on discussions with the ACTuate team, we identified occurrences of malfunctions and selected a suitable model structure to analyze the temperature data from freezers and coolers. By fitting this model to the data, we can detect unusual system behavior. The process is entirely data-driven.

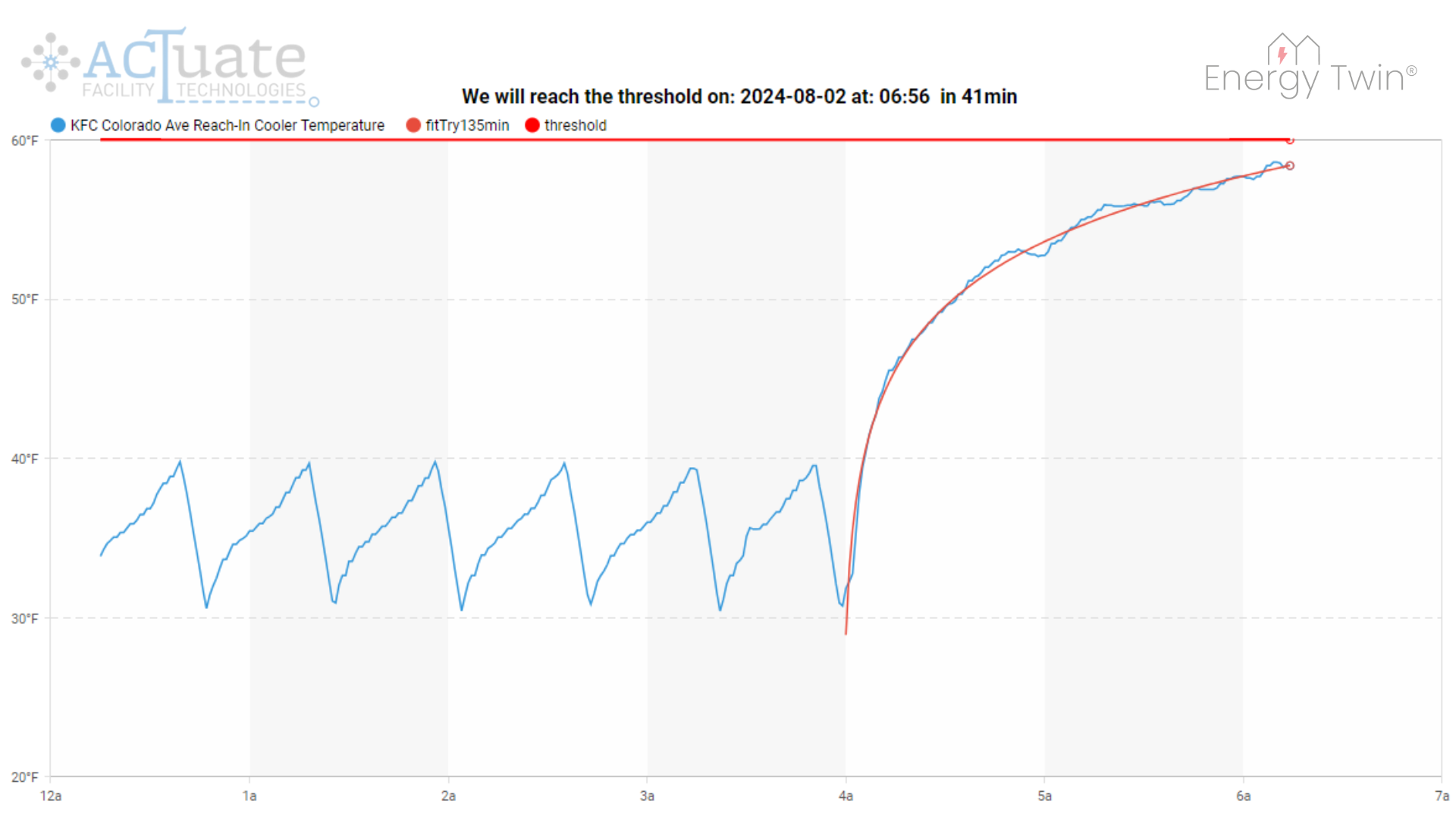

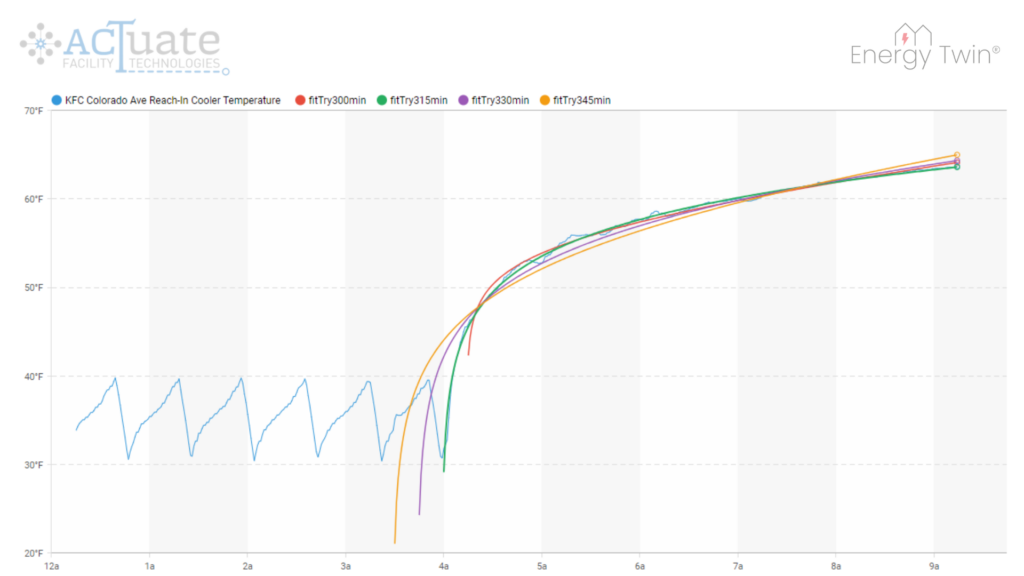

Our optimization techniques involve using a fluctuating window of past data, which dynamically adjusts in length based on the fit quality. The accuracy of this fit is measured by performance metrics, including Mean Absolute Error (MAE) as can be seen in the picture below.

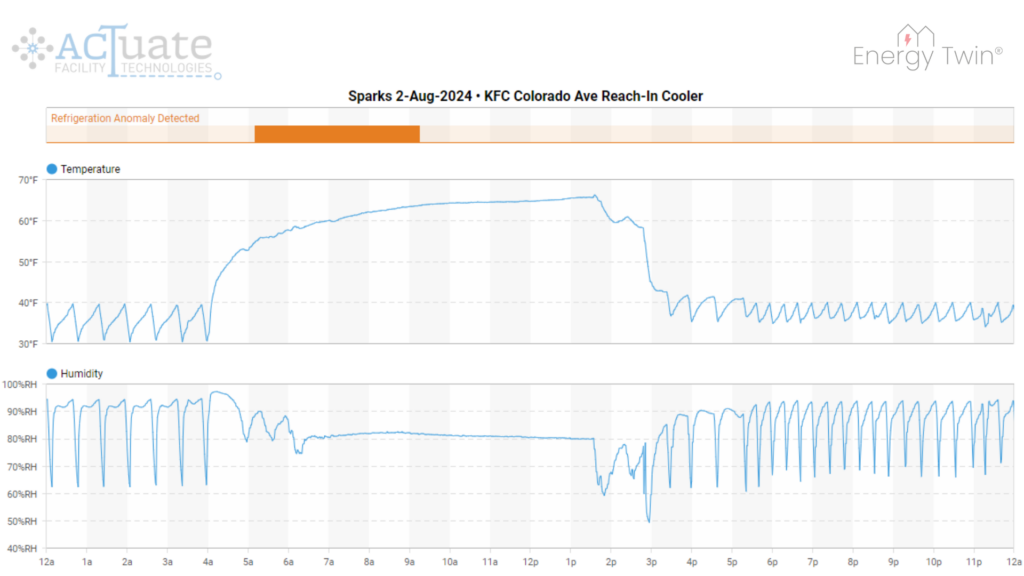

Transforming Data Modeling into Anomaly Detection Rule

One of the most compelling aspects of our collaboration with the ACTuate team is the development of an active detection rule based on data modeling. This approach not only allows us to analyze past temperature data but also transforms that analysis into a proactive monitoring system.

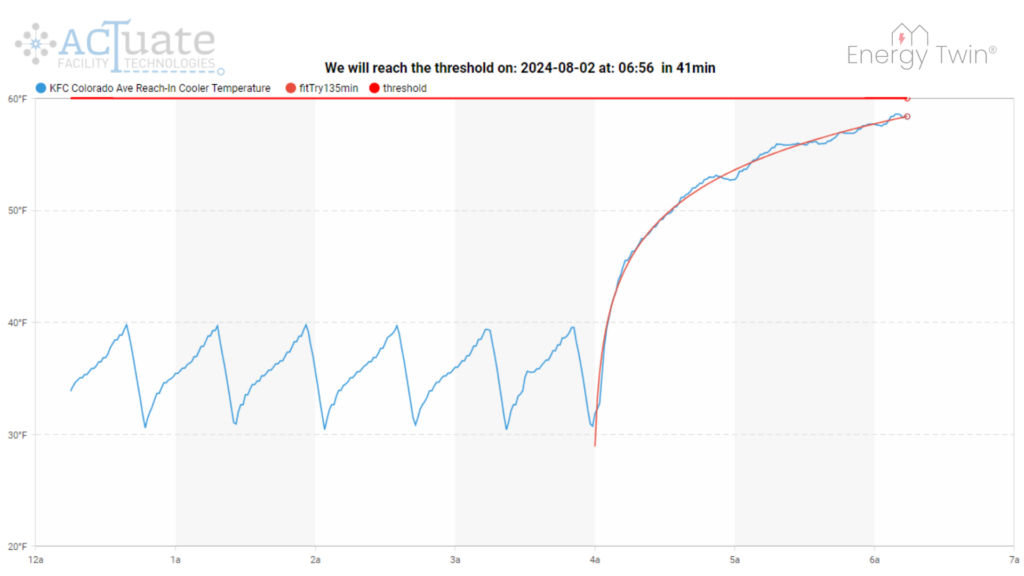

Real-Time Monitoring

With real-time data, you can also use the data modeling to predict if certain thresholds will be breached and communicate with the on-site team about the necessary actions. Sometimes it can be as simple as a reminder to “close the door.”

Conclusion

Through our collaboration with ACTuate Facility Technologies, we have developed a sophisticated approach to monitoring and detecting unusual behavior in refrigeration systems. While our efforts contribute to significant energy savings, the primary objective is to reduce the number of incidents where temperature deviations lead to costly spoilage, ultimately ensuring the safety and quality of the stored product.